CINS and P&I Clubs publish guidelines for Lithium-Ion batteries onboard containers

In conjunction with the International Group of P&I Clubs, TT Club and ICHCA, Cargo Incident Notification System (CINS) published a report on transporting batteries inside containers titled “Lithium-Ion Batteries in Containers Guidelines”.

According to the report, all stakeholders involved in the carriage of Lithium‐Ion Batteries in containers are asked to carefully review these CINS Guidelines to determine if they can be implemented and applied to their specific operations and requirements. CINS will update these Guidelines as required, as new technological‐methodological solutions are evolved and developed.

The main challenges are:

- The proper classification of the Lithium‐Ion Batteries, including the proper division in accordance with the power and energy storage capacity.

- Quality of Lithium‐Ion Batteries, and compliance with the Test Summaries.

- Correct declaration and the responsibilities of shippers, forwarders, manufacturers, and producers.

- Implementation of an effective supply chain and Know Your Customer (KYC) programme.

- Compliance with the relevant regulations including, but not limited to, the IMDG and CTU Codes, and proper completion of the Shippers Declaration and

- Packing Declarations. This is mandatory for Lithium‐Ion Batteries classified as dangerous cargoes but could be initiated for Lithium‐Ion Batteries that are declared under SP188 of the IMDG Code and which are considered as less dangerous, but nevertheless must be considered as “critical” (Critical Cargo Declaration and Packing Certificate). This can be considered by each individual ship operator.

- Container and cargo inspections and vanning surveys. This can be considered by each individual ship operator.

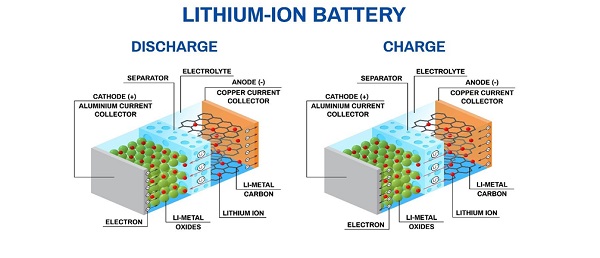

Parts and Operation of a Lithium‐Ion Battery

Lithium‐Ion Batteries have the highest charge density of any comparable system. This means they can provide a lot of energy relative to their weight. A lithium‐ion battery is made up of several individual cells that are connected to one another. Each cell contains three main parts: a positive electrode (a cathode), a negative electrode (an anode) and an electrolyte.

If the separator is damaged, the electrodes can touch each other, causing electrical short circuit and significant Joule heating which triggers thermal runaway. The heat in a single cell is rapidly transferred from cell to cell in a cascading effect called thermal propagation. Eventually, the gases are vented from the cell, taking with them droplets of the organic solvent producing a white vapour cloud.

If this ignites immediately, long flare‐like flames are produced. If ignition is delayed, a vapour cloud explosion can occur, and indeed such VCEs have occurred involving Lithium‐ion Batteries in E‐scooters as well as grid‐scale Battery Energy Storage Systems (BESS).

Lithium-ion battery cargo issues

Under certain conditions there may be an increase in the internal temperature of a lithium‐ ion cell, which in turn can initiate exothermic reactions (these are reactions which release heat). This can create a heat‐temperature loop, leading to higher internal temperatures and further exothermic reactions.

If this heat does not dissipate, the battery cell temperature will elevate further, thereby accelerating the process of heat release. The battery enters an uncontrollable, self‐heating state.

This process is called thermal runaway. Thermal runaway will affect neighbouring cells in the battery and adjacent batteries, as well as other substances and commodities in the vicinity. These exothermic reactions can give off oxygen enabling combustion.

| Read More: North P&I launches mobile app to ease evidence gathering burden for marine professionals |

Triggers for thermal runaway:

- Electrical abuse (over‐charging/discharging)

- Thermal abuse (over‐temperature)

- Mechanical abuse (penetration, pinch, and bend)

- Internal short circuit

- Contaminants in Lithium‐Ion Batteries

- Lithium‐Ion Battery Quality

Lithium‐Ion Battery Hazards

a) Fire

The consequences of a Lithium‐Ion Battery fire can be severe. Typical fire risks, whether on board ship or ashore, are:

- Thermal runaway events and conditions

- Fire suppression

- The effects of thermal runaway may start a fire which is difficult to extinguish. Normal fire extinguishing tools and materials may not be efficient and/or sufficient.

- Fire propagation and heat flux

- Another effect is related to the related reactivity characteristics and the heat flux of the materials in the vicinity of the fire. Especially when other Lithium‐Ion Batteries are in the direct vicinity. This is known as “fire propagation”.

- Fire and explosion

- The reaction and fire may evolve into an explosion, depending on the circumstances.

b) Toxicity

Thermal runaway reaction products contain many toxic substances, and prevention and protection is necessary. The substances are very toxic, highly toxic, and toxic which are the three most dangerous levels of poison classified under China National Standards.

These toxicity characteristics are applicable not only to the gas cloud and to the residue that remains after the fire. The thermal gas reactions generated different type of toxicity risks that were directly related to the state of charge of the Lithium‐Ion Battery with a battery at 100% state of charge being the most dangerous in terms of toxicity and hazards.

Loss prevention

Main proposals

- Address vulnerabilities to thermal runaway cascading, ventilation, and suppression in existing and operational Lithium‐Ion Battery packaged systems in containers.

- Update industry standards, transport regulations and codes to directly address cascading thermal runaway in Lithium‐Ion Batteries and future energy storage systems.

- Develop performance‐based standards for Lithium‐Ion Batteries based on the principle that dangerous effects will be contained within the package.

- Develop ventilation and extinguishing or cooling systems to manage thermal runaway, especially in battery energy storage systems.

- Develop Lithium‐Ion Battery and battery energy storage systems designs that aim to slow or halt cascading or propagation of battery cells and modules during thermal runaway.

- Develop education, training, and emergency response procedures that account for the risks and hazards of cascading thermal runaway—including toxic and flammable gases—and how to enter containers after a fire.

- Introduce transparency related to factory audit and supply chain know your customer procedures.

- Introduce Lithium‐Ion Battery cargo screening, inspections, and vanning surveys.

- Apply the same packaging instructions for maritime transport as for aviation.

- Research and consider new Fire Fighting Techniques, such as new “aerosol techniques”.

- Introduce early warning systems from specific Lithium‐Ion Battery “off gas” detection systems.

Source: Safety4sea

| Read Here | |

|

|